Here’s a great example of why graphic design leans more towards science than art. When designing something for print, the topic of “Rich Black” may come up, so here are a few questions to think about before continuing:

- What is “Rich Black”?

- Why is rich black not made up of 100% of CMYK?

- When should rich black be used (and avoided)?

What is “Rich Black”?

Rich black is a combination of black with one or more other colors. If you have ever used the color “Registration”, you have utilized rich black. There are a few benefits of using rich black in printing: it deepens the tone of black, it can be used to hide print imperfections in one-color black, and on opaque materials can greatly reduce the amount of light passing through. Rich black is also utilized to line-up color separations. This process is called “registration”.

Why is rich black not made up of 100% CMYK?

There are many reasons to be careful with deciding the percent of ink to lay down for rich black. Too little and it is may not be noticeable enough to constitute paying for multiple plates, but too much and you risk other problems. So what, scientifically, determines the amount of ink to use for rich black? Surface tension of the ink vs. surface energy of the material. One way to determine the surface energy of a material is by dyne testing. Oversimplified: a low dyne level means ink will spread well, but a high level means ink will form droplets and not be absorbed by the material. In other words: use too much ink and you will get “rub off” (or smearing). However, dyne testing is an impractical method when it comes to a design standpoint. It would not be time-effective to change the percentages of rich black to customize it for each individual material.

Another reason that rich black should not be 100% CMYK is that the substrate may not be thick enough to support that much ink. A paper towel is much easier to break when saturated with water. If you were to print 100% of four color process onto a newspaper material, it would become very weak. 100% CMYK should be limited to “Registration”.

From a semantic standpoint, 100% CMYK is not quite the same as “Registration” (the noun, not the verb). If you were to create a document using four color process and a spot color once using 100% CMYK and again using registration, you will see two different results on press. Registration is 100% CMYK in addition to 100% of all spot colors in the document (we’ll assume color values are all 100%). This allows operators to line-up color separations including spot colors.

Semantics aside, why can the color registration be used on weak materials, but 100% CMYK can not? A few reasons: 1: Registration is used in very small areas. Typically only in crop marks and other elements for aligning plates. 2: Areas using registration as a color are usually cut off and not found on the final product. Registration should not be used for anything besides production elements.

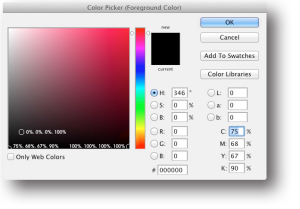

Back to the question at hand. What values should be used for rich black without causing rub off or material weakening? It’s entirely subjective! There is no definitive answer for specifically what percentages you should use. There are a TON of variables that will effect the amount of black from amount of impression (on impression-based printers) to the color cast of the material itself, to the type of printer being used. Some designers like a cool black (cyan-shifted) using 40%, 0%, 0%, 100%, and others like to apply 40% to magenta. Personally, I prefer an even laydown of CMY around 40-50% with 100% black. While some printers may recommend using 100% CMYK, I would avoid it at all costs unless you know what you are doing.

Back to the question at hand. What values should be used for rich black without causing rub off or material weakening? It’s entirely subjective! There is no definitive answer for specifically what percentages you should use. There are a TON of variables that will effect the amount of black from amount of impression (on impression-based printers) to the color cast of the material itself, to the type of printer being used. Some designers like a cool black (cyan-shifted) using 40%, 0%, 0%, 100%, and others like to apply 40% to magenta. Personally, I prefer an even laydown of CMY around 40-50% with 100% black. While some printers may recommend using 100% CMYK, I would avoid it at all costs unless you know what you are doing.

When should rich black be used (and avoided)?

This technique should be used to achieve a darker, more deep shade of black. It can be applied to imagery and other objects. However, there are many situations to avoid rich black entirely! Body copy should not use rich black. For the same reason you should not use it for line work, small type will be very difficult (and impossible on some presses) to register. Another place to stay away from rich black is for small knockouts (or dropouts) including type or objects. This will also cause registration problems, and a bunch of angry press operators is never a good thing.

Digital press technology may encourage rich black for printing. Large format printers may encourage using rich black for very large areas such as backgrounds. Registration is much more forgiving on digital presses, so the practice is used with less worry. Be careful, though- just because you know a design is printing digitally does not mean you should assume rich black is desired.

You can always ask your printer how they would like the file set up (and see if you can speak directly to an operator). Sending in a file correctly will save much prepress time and money, so it is worth the time to research the print method and develop art accordingly.

I like to recommend that people buy a cheap pocket loupe, because they are handy to have around when you want to diagnose a print! Here’s my personal favorite (since it folds up to travel easily):

While we’re on the subject of the color black: why is black represented with a K in CMYK?